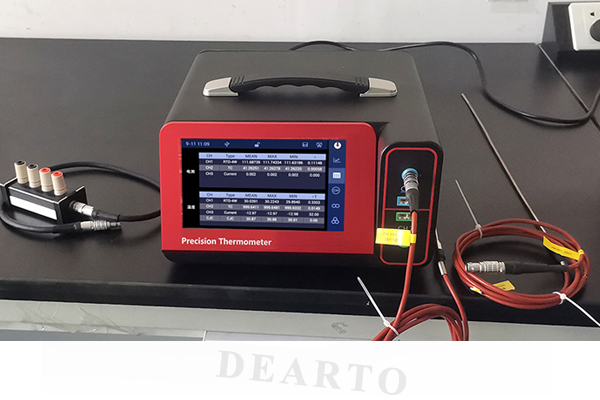

mK Grade High-Precision Thermometer Readout

Introduction

The DTMC-mK301 is a new-generation, multi-channel, ultra-high-precision thermometer readout developed for temperature metrology and calibration. It integrates high-accuracy electrical measurement technology, intelligent interface design, and application-specific functions to fully meet the calibration needs of both laboratories and fieldwork. The DTMC-mK301 measures: standard and industrial RTDs, thermocouples, thermistors, temperature transmitters, humidity sensors, DC current, resistance, and voltage signals. It supports ITS-90 and IEC 60751 standards and features built-in thermophysical conversion tools, intelligent sensor management, and broad compatibility across industries such as power, petrochemical, metrology, metallurgy, biotechnology, pharmaceuticals, and scientific research.

mK-Grade Precision Thermometer Readout

· Resolution: 0.00001 °C

· Accuracy: 5 ppm @ 0 °C (using SPRT)

Channels & Sensor Support

· 3 input channels: CH1 and CH2 (front), CH3 (rear)

· Supports 2 standard platinum resistance thermometers (SPRT), 2 standard thermocouples

· Supports RTDs: Pt (Pt25, Pt100, PtX), Cu (CuX), and Ni (NiX)

· Supports thermocouples: K, N, J, E, T, R, S, B, WRe3, WRe5

· Supports thermistors: 0 kΩ to 40 kΩ

· Supports temperature transmitters: 0 mA to 20 mA / 4 mA to 20 mA

· Automatic current reversal for RTD input to eliminate EMF thermal voltage error

Thermocouple Cold Junction Compensation

· Multiple compensation modes supported: internal compensation, external compensation, fixed compensation

Multiple Conversion Algorithms Supported

· ITS-90, Callendar-Van Dusen, IEC 60751:2008, polynomial equations, Steinhart–Hart, B-Value, linear conversion

Sensor Management Features

· Supports management of up to 100 sensor profiles

· Editable sensor parameters improve measurement accuracy

Smart Sensor Capability

· Automatic detection and data upload when a smart sensor is connected

Smart Terminal Box Support

· Stores and auto-uploads SPRT certificate values

· Plug-and-play operation; no need to manually input certificate data

User Interface & Display Modes

· Five display modes: single-channel, dual-channel, triple-channel, curve display, table display

· Real-time display of sensor information, measurement data, and trends

· Automatic statistical analysis: max, min, average, peak-to-peak, standard deviation, stability, etc.

· Real-time curve plotting

· 7-inch high-resolution capacitive touchscreen

Thermophysical Calculator

· Built-in thermophysical calculator

· Integrated ITS-90 fixed-point reference data

Data Logging & Storage

· Timestamped data recording

· 8 GB internal storage; external USB drive supported

· SCPI communication protocol over RS232/WLAN

· Screenshot feature available on all display screens, no need for manual data recording

|

Model |

DTMC-mK301G-PRT |

DTMC-mK301G |

DTHPA-mK301G |

|

Multi-channel temperature meter |

● |

● |

● |

|

DC multimeter |

|

|

● |

|

Sensor testing |

|

● |

|

|

SPRT/RTD Measurement |

● |

● |

● |

|

RTC/TC Measurement |

|

● |

● |

|

Transmitter |

● |

● |

● |

|

Thermistor Measurement |

● |

● |

● |

|

Temperature switch test |

|

● |

|

|

Constant temperature source test |

● |

● |

● |

|

Electronic scanning switch |

● |

● |

● |

|

Smart Sensors |

● |

● |

|

|

Smart Junction Box |

● |

● |

|

|

Thermal Calculator |

● |

● |

● |

|

Sensor Management |

● |

● |

● |

|

Data storage |

● |

● |

● |

|

Smart Communications |

● |

● |

● |

Technical Parameters

|

Electrical test indicators |

|||||

|

Applicable Models |

DTMC-mK301GH |

DTMC-mK301G |

|||

|

Channel Type |

Range |

Input range |

Resolution |

Accuracy(1 year) |

|

|

SPRT 25 |

120Ω |

0Ω to 125Ω |

0.01mΩ |

15ppm+3ppm |

30ppm+5ppm |

|

SPRT 100 |

400Ω |

0Ω to 400Ω |

0.01mΩ |

15ppm+3ppm |

30ppm+5ppm |

|

PRT |

100Ω |

0Ω to 110Ω |

0.01mΩ |

15ppm+3ppm |

30ppm+5ppm |

|

PRT |

400Ω |

0Ω to 410Ω |

0.01mΩ |

15ppm+3ppm |

30ppm+5ppm |

|

PRT |

1KΩ |

0Ω to 1.1KΩ |

0.01mΩ |

28ppm+1ppm |

30ppm+1ppm |

|

PRT |

4KΩ |

0Ω to 4.1KΩ |

0.01mΩ |

28ppm+1ppm |

30ppm+1ppm |

|

TC |

30mV |

-35mV to 35mV |

10nV |

36ppm+6ppm |

40ppm+7ppm |

|

TC |

100mV |

-120mV to 120mV |

10nV |

36ppm+6ppm |

40ppm+7ppm |

|

DCV |

1V |

-1V to 1V |

10nV |

30ppm+2ppm |

30ppm+2ppm |

|

DCV |

10V |

-10V to 10V |

10nV |

30ppm+2ppm |

30ppm+2ppm |

|

Transmitter |

25mA |

0mA~25mA |

0.001mA |

0.02% |

0.02% |

|

Note: The test environment temperature specification conditions are 1 hour warm-up time; The environment temperature is 20℃ ±1℃; The environment relative humidity is 40%RH |

|||||

|

Temperature index |

|||

|

Type |

Graduation |

Temp.range |

Accuracy |

|

SPRT |

Pt25 |

-189 ℃ to 660 ℃ |

0.0033 ℃@-200 ℃ 0.0060 ℃@0 ℃ 0.0100 ℃@100 ℃ 0.0180 ℃@300 ℃ 0.0280 ℃@600 ℃ |

|

Pt100 |

-189 ℃ to 660 ℃ |

0.0033 ℃@-200 ℃ 0.0060℃@0 ℃ 0.0100 ℃@100 ℃ 0.0180 ℃@300 ℃ 0.0280 ℃@600 ℃ |

|

|

PRT |

PT10 |

-189 ℃ to 961 ℃ -200 ℃ to 740 ℃ |

0.005℃@-200 ℃ 0.0009℃@-100 ℃ 0.012℃@0 ℃ 0.031 ℃@600 ℃ |

|

Pt100 |

-189 ℃ to 961 ℃ -200 ℃ to 740 ℃ |

0.0080℃@0 ℃ 0.0185 ℃@300 ℃ 0.0280 ℃@600 ℃ |

|

|

PT200 |

-189 ℃ to 961 ℃ -200 ℃ to 740 ℃ |

0.0020℃@-200 ℃ 0.0048℃@-100 ℃ 0.0300 ℃@600 ℃ |

|

|

TC |

K |

-270 ℃ to 1370 ℃ -100 ℃ to 1300 ℃ |

0.038℃@600℃ 0.050℃@1000℃ |

|

N |

-270 ℃ to 1300 ℃ -200 ℃ to 1300 ℃ |

0.038℃@600℃; 0.050℃@1000℃ |

|

|

J |

-210 ℃ to 1200 ℃ -100 ℃ to 900 ℃ |

0.018℃@300℃ 0.026℃@600℃ |

|

|

E |

-210 ℃ to 1000 ℃ -90 ℃ to 700 ℃ |

0.020℃@300℃; 0.028℃@600℃ |

|

|

T |

-270 ℃ to 400 ℃ -150 ℃ to 400 ℃ |

0.01℃@0℃; 0.02℃@200℃ |

|

|

R |

-50 ℃ to 1760 ℃ 0 ℃ to 1760 ℃ |

0.055℃@300℃; 0.06℃@600℃; 0.08℃@1000℃ |

|

|

S |

-50 ℃ to 1760 ℃ 0 ℃ to 1760 ℃ |

||

|

B |

250 ℃ to 1820 ℃ 300 ℃ to 1800 ℃ |

0.07℃@1000℃; 0.068℃@1200℃; 0.088℃@1800℃ |

|

|

Remarks: It doesn’t include the sensor's own deviation |

|

||

|

Function parameters |

||

|

Function |

Type |

Description |

|

Channels |

3 |

CH1 & CH2 (front),CH3(rear).External 8-Channel Electronic Scanning Switch (Optional) |

|

Input |

CH1/CH2 |

TC/RTD |

|

CH3 |

Current |

|

|

Input Connectors |

Thermal resistor (front panel) |

Lemo EPG.1B.306.HLN 6-pin connector |

|

Thermal resistor (rear panel) |

4mm Low-thermal posts |

|

|

TC |

Mini TC Connectors(ASTM E 1684-05) |

|

|

Drive current |

SPRT/PRT |

1mA(±0.1%)(Auto-reversing) |

|

Cold Junction Compensation(CJC) |

|

Built-in cold junction compensation External Cold Junction Compensation (CJC) CH1 and CH2 can be CJC to each other User-defined cold junction temperature. |

|

Cold junction compensation accuracy |

|

±0.1℃ |

|

Smart Sensors |

SPRT/PRT |

Support |

|

Sensors Management Quantity |

|

100 Pcs |

|

Sensor Management |

Conversion formula |

ITS-90 IEC60751(2008), Callendar-van Dusen Steinhart-Hart, polynomial B Value Multinomial |

|

Sensor support |

RTD |

SPRT Pt25/Pt100 PRT: Pt100/Pt1000/Pt-X Copper resistor: Cu50/Cu100/Cu-X Nickel resistor:Ni50/Ni120/Ni1000 Thermistor:(0-40K) |

|

TC |

Standard Thermocouple: B/S Industrial Thermocouples: K/N/J/E/T/R/S/B/WRe3/WRe5 |

|

|

Transmitter |

Temperature transmitter:(0-20mA/4-20mA) |

|

|

Sensor |

Type / index |

Temperature range (°C) |

Coefficients |

Freezing point |

|

Standard platinum resistance thermometer (SPRT) |

SPRT |

0 to 660.323 |

a7, b7, c7 |

Stannum (WSₙ), Zinc (WZn), Aluminum (WAl) |

|

0 to 419.527 |

a8, b8 |

Stannum (WSₙ), Zinc (WZn) |

||

|

0 to 231.928 |

a9, b9 |

Stannum (WSₙ), Indium (WIn) |

||

|

-189.834 to 0 |

a4, b4 |

Argon triple point (WAr), Mercury triple point (WHg) |

||

|

0 to 156.5985 |

a10 |

Indium (WIn) |

||

|

0 to 29.7646 |

a11 |

Gallium melting point (WGa) |

||

|

-38.8344 to 29.7646 |

a5, b5 |

Gallium melting point (WGa), Mercury triple point (WHg) |

||

|

Industrial RTDs |

Pt100 |

-200 to 850 |

/ |

|

|

Cu100 |

-50 to 150 |

|||

|

Standard thermocouples (RTC) |

S (Standard) |

300 to 1300 |

||

|

B (Standard) |

0 to 1820 |

|||

|

Industrial thermocouples (TC) |

S |

-50 to 1760 |

||

|

R |

-50 to 1761 |

|||

|

B |

0 to 1820 |

|||

|

K |

-270 to 1370 |

|||

|

N |

-270 to 1300 |

|||

|

E |

-270 to 1000 |

|||

|

J |

-210 to 1200 |

|||

|

T |

-270 to 400 |

|||

|

WRe3 (D) |

0 to 2310 |

|||

|

WRe5 (C) |

0 to 2311 |

|||