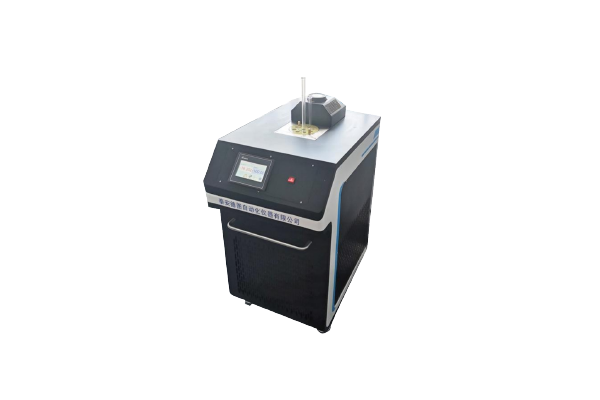

Efficient Intelligent Temperature Field Constant Temperature Equipment

● High Stability: Intelligent PID control, with excellent temperature field stability and uniformity

● Accurate: High resolution display instrument, resolution 0.001℃

● Customizable: Special index products can be customized according to requirements.

● Automatic Calibration: Support multi-point automatic calibration and correction.

Liquid Calibration Bath Series Product Selection Table

| Product number | DTS-CT300G | DTS-CT95G | DTS-CT01G | DTS-CT10G |

|---|---|---|---|---|

| Temperature range (°C) | 70~300 | RT+10~95 | 0~100 | -10~100 |

| Fluctuation (℃/10min) | ±0.007 | ±0.01 | ±0.01 | ±0.01 |

| Uniformity(℃)) | ≤0.01 | ≤0.01 | ≤0.01 | ≤0.01 |

| Working medium | silicone oil | soft water, antifreeze | antifreeze | |

| Volume(L) | 23 | 18.5 | 18.5 | 18.5 |

| Work area size(mm) | Φ150×480 | Φ130×480 | ||

| Dimensions(mm) | 660(L)×540(W)×1120(H) | |||

| Intelligent Low Temperature Calibration Bath | ||||

| Product number | DTS-CT30G | DTS-CT40G | DTS-CT60G | DTS-CT80G |

| Temperature range (°C) | -30~100 | -40~100 | -60~100 | -80~100 |

| Fluctuation (℃/10min) | ±0.01 | ±0.01 | ±0.01 | ±0.01 |

| Uniformity(℃)) | ≤0.01 | ≤0.01 | ≤0.01 | ≤0.01 |

| Working medium | antifreeze | Absolute ethanol | ||

| Volume(L) | 18.5 | 18.5 | ||

| Work area size(mm) | Φ130×480 | Φ130×480 | ||

| Dimensions(mm) | 660(L)×540(W)×1120(H) | 700(L)×590(W)×1120(H) | ||

Precision Calibration Bath

| Product number | DTS-300G | DTS-95G | DTS-01G | DTS-10G |

|---|---|---|---|---|

| Temperature range (°C) | 70~300 | RT+10~95 | 0~100 | -10~100 |

| Fluctuation (℃/10min) | ±0.007 | ±0.01 | ±0.01 | |

| Uniformity(℃)) | ≤0.01 | ≤0.01 | ≤0.01 | |

| Working medium | silicone oil | soft water, antifreeze | antifreeze | |

| Volume(L) | 23 | 18.5 | 18.5 | |

| Work area size(mm) | Φ150×480 | Φ130×480 | ||

| Dimensions(mm) | 660(L)×540(W)×1120(H) | |||

| Precision Low Temperature Calibration Bath | ||||

| Product number | DTS-30G | DTS-40G | DTS-60G | DTS-80G |

| Temperature range (°C) | -30~100 | -40~100 | -60~100 | -80~100 |

| Fluctuation (℃/10min) | ±0.01 | ±0.01 | ||

| Uniformity(℃)) | ≤0.01 | ≤0.01 | ||

| Working medium | antifreeze | Absolute ethanol | ||

| Volume(L) | 18.5 | 18.5 | ||

| Work area size(mm) | Φ130×480 | Φ130×480 | ||

| Dimensions(mm) | 660(L)×540(W)×1120(H) | 700(L)×590(W)×1120(H) | ||

High and Low Temperature Calibration Bath

| Product number | DTS-CT150G | DTS-CT180G | DTS-T150G | DTS-T180G | DTS-T300G |

|---|---|---|---|---|---|

| Way to control | Intelligent Screen Control | Precision Instrument Control | Cycle rapid cooling | ||

| Temperature range (°C) | -20~150 | -20~180 | -20~150 | -20~180 | 70~300 |

| -30~150 | -30~180 | -30~150 | -30~180 | ||

| Volume(L) | 18 | 18 | 23 | ||

| Work area size(mm) | Φ130×480 | Φ150×480 | |||

Triple Point of Water Maintenance Bath

| Product numbe | DTF-CT01SG | DTF-CT30SG | DTF-01SG | DTF-30SG | DTF-01G |

|---|---|---|---|---|---|

| Temperature range (°C) | -10~105 | -30~105 | -10~105 | -30~105 | -10~105 |

| Way to control | Intelligent Screen Control | Precision Instrument Control | Regular Control | ||

| Product type | One bath for three purposes (water triple point freezer, water triple point saver, refrigeration calibration bath) | Standard type | |||

| Fluctuation (℃/30min) | ±0.005 | ||||

| Uniformity(℃)) | ≤0.01 | ||||

| Working medium | antifreeze | ||||

| Frozen quantity (branches) | 1~3 | ||||

| Dimensions (mm) | 660(L)×540(W)×1120(H) | ||||

High Temperature Precision Salt Bath

| Product numbe | DTW-560BG | DTW-560G | DTW-670G |

|---|---|---|---|

| Temperature range (°C) | 180~560 | 180~560 | 450~670 |

| Work area size(mm) | Φ80×200 | Φ140×400 | |

| Power (KW) | 1 | 2.5 | |

| Fluctuation (℃/10min) | ±0.01 | ||

| Horizontal uniformity (°C) | ≤0.01 | ||

| Vertical uniformity (°C) | ≤0.02 | ||

Ultra-low Temperature Precision Calibration Bath

| Product numbe | DTS-100CHG | DTS-160CHG | DTS-180CHG | DTS-60CH-BG | DTS-100CH-BG |

|---|---|---|---|---|---|

| Temperature range (°C) | -100~95 | -160~-40 | -180~-40 | -60~95 | -100~95 |

| Work area size(mm) | Φ130×480 | 6个,Φ12×280 | Φ100×300 | ||

| Dimensions (mm) | 800×600×1000 | 500×620×600 | 320×480×530 | 420×510×700 | |

| Fluctuation (℃/30min) | ±0.01 | ±0.03 | ±0.01 | ||

| Uniformity (°C) | ≤0.01 | ≤0.01 | ≤0.01 | ||

Super Large Diameter Precision Calibration Bath

| Product numbe | DTS-300-T500G | DTS-10-T500G | DTS-30-T500G | DTS-80-T500G |

|---|---|---|---|---|

| Temperature range (°C) | 70~300 | -10~95 | -30~95 | -80~95 |

| Work area size(mm) | Φ300×480 / Φ500×480 (support special customization) | |||

| Fluctuation (℃/30min) | ±0.01 | |||

| Uniformity (°C) | ≤0.01 | |||

| Volume(L) | 120 | |||

Ultra-Portable Intelligent Calibration Bath

| Product numbe | DTS-300BG | DTS-10BG | DTS-20BG | DTS-30BG | DTS-40BG | DTS-95BG | DTS-125BG |

|---|---|---|---|---|---|---|---|

| Temperature range (°C) | 60~300 | -10~150 | -20~150 | -30~150 | -40~150 | -40~95 | -40~125 |

| -10~180 | -20~180 | -30~180 | -40~180 | ||||

| Work area size(mm) | Φ80×280 / Φ100×280(The opening diameter supports customization) | ||||||

| Dimensions (mm) | 425×220×370 | 430×225×500 | |||||

| Working medium | silicone oil | special medium(L40N-180) | |||||

Liquid Calibration Bath: Guide

In this guide, you will learn all about.

1: What is a Liquid Calibration Bath?

2: How Liquid Calibration Baths Work?

Liquid Calibration Baths maintain a controlled temperature environment using a specific calibration liquid (e.g., oils) to immerse temperature-sensitive instruments. The instrument’s readings are compared to a reference temperature, and adjustments are made to ensure accuracy.

3: Advantages of Using Liquid Calibration Baths

- Precision Accuracy

- Rapid Cooling & heating

- Intuitive PiD Display

- Steadfast Stability

4: Types of Liquid Calibration Baths

- Oil Baths: For high-temperature calibrations.

- Water Baths: For lower to moderate temperatures.

- Dry Block Baths: Use metal blocks instead of liquid for smaller instruments.

- Salt Baths: For extremely high-temperature calibrations.

- Metal Baths: Use molten metal for calibrating at very high temperatures.

5: Calibration Procedure Using a Liquid Calibration Bath

- Prepare the bath with the appropriate liquid and ensure cleanliness.

- Set the temperature and allow it to stabilize.

- Submerge the sensor, ensuring full immersion.

- Adjust and calibrate based on reference readings.

- Record the results for documentation and quality control.

6: Applications of Liquid Calibration Baths

- Pharmaceuticals and Healthcare: Ensures accuracy in temperature-controlled environments.

- Food and Beverage: Used for food safety and quality control.

- Aerospace and Defense: Calibrates sensors for extreme conditions.

- Research and Development: Supports accurate experimental data.

- Automotive Industry: Calibrates instruments for performance and compliance.

In the End

Ultimately, liquid calibration baths became an indispensable tool in every industry and research field, serving as the cornerstone for accurate temperature measurement and instrument calibration. Their high precision, stability and versatility make them essential for ensuring product quality, compliance with industry standards and reliable scientific research.

By understanding the factors to consider when selecting a liquid calibration bath, organizations and laboratories can make an informed decision and choose the bath that best suits their specific calibration needs. Whether it is a standard liquid calibration bath or a custom solution, reputable manufacturers such as Dearto offer a wide range of options to meet different calibration requirements.