Overview:

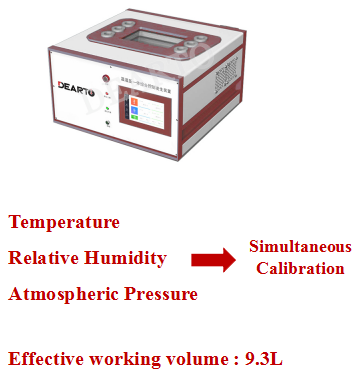

TADT-atm temp-humidity-pressure integrated control generator is specially developed to meet the calibration needs of meteorological units for motor vehicle testing.TADT-atm is a high-end measuring device that accurately measures key parameters such as temperature, relative humidity and atmospheric pressure in the vehicle testing environment.

It can accurately simulate the temperature, relative humidity and atmospheric pressure under different conditions to ensure the accuracy and efficiency of the calibration work of the meteorological unit; it is mainly used in motor vehicle testing stations, metrological testing organizations and scientific research institutes to help ensure the accuracy of the measurement of the meteorological unit, and then improve the accuracy of the motor vehicle testing results.

Product Features

1.Integrated multi-parameter calibration:Temperature, relative humidity and atmospheric pressure can be calibrated at the same time, eliminating the cumbersome process of using multiple devices to calibrate separately, and dramatically improving calibration efficiency.

2.Real-time curve display:

With powerful data visualization capabilities, it supports real-time display of temperature, humidity and pressure curves, which is convenient for users to intuitively grasp the trend of data changes.

3.Intelligent conversion software:

The instrument has built-in professional humidity conversion software, which can quickly convert relative humidity, temperature and dew point temperature, providing users with more data reference.

4.Intuitive user interface:

Equipped with 7 inch color LCD touch screen, the operation interface design is simple and intuitive, bringing users a convenient interactive experience.

5.Precision calibration function:

Supports multi-point correction for temperature, humidity, and pressure to ensure the reliability of measurement data.

6.Communication interface:

Supports RS232 or RS485 communication for easy data transmission and system integration with other devices.

7.Split power communication:

Provide split inspected sensor power supply communication module, effectively enhance the flexibility and adaptability of the equipment to meet the use of different scenarios.

8.Flexible calibration point settings:

Temperature calibration contains -10℃, 0℃, 20℃, 30℃, 40℃ and other calibration points, the calibration sequence is scientific and reasonable, first calibrate the negative temperature point and then gradually increase the temperature, effectively preventing the phenomenon of frost; Relative humidity calibration points contain 30%, 50% and 80%, accurately covering the common humiditycalibration interval, to meet the needs of calibration in different humidity environments; Atmospheric pressure calibration points can be based on the local conventional atmospheric pressure,The atmospheric pressure calibration points can be set flexibly according to the local conventional atmospheric pressure, upper and lower atmospheric pressure limits, fully taking into account the actual situation of different regions to ensure the accuracy and practicability of the calibration results.

9.Efficient structural design:

The measuring chamber is equipped with transparent window and illumination design, which is convenient for reading data of various small temperature and humidity meters; the external drying cylinder design makes the desiccant replacement can be operated online under power-on condition; the dual-area drying cylinder design supports two kinds of desiccants, namely, molecular sieve and color-changing silica gel at the same time; and the intuitive liquid level and desiccant status display is convenient for the monitoring of the status in the working process.

10.Standardized and efficient calibration process:

Preparation before calibration is simple, after warming up, put the sensor of the weather unit under calibration into the center of the calibration chamber, close the lid of the calibration chamber to start calibration.During the calibration process, after each calibration point reaches the set value and is balanced, the data is recorded at minute intervals to ensure that the calibration work is carried out in an efficient and orderly manner, providing users with reliable calibration results.

Technical Parameters

|

Temperature indicators

|

Relative Humidity indicators

|

Atmospheric pressure indicators

|

|

Temperature range

|

-20℃ ~ 50℃

|

Humidity range

|

5%RH ~ 95%RH(20℃)

|

Pressure range

|

50 kPa ~ 120 kPa

|

|

Maximum allowable tolerance

|

≤ ±0.1℃

|

Maximum allowable tolerance

|

≤ ±0.8%RH

|

Pressure sensor accuracy rating

|

0.1 level

|

|

Rate of change of temperature

|

≤ ±0.2℃ / min

(-20℃ ~ 50℃)

|

Rate of change of temperature

|

≤ ±0.8%RH/min

( 20℃ )

|

Pressure stability

|

≤ 0.1kPa / min

|

|

Temperature uniformity

|

≤ 0.1℃

(10℃ ~ 30℃)

|

Humidity uniformity |

≤ 0.5%RH

( 5%RH ~ 30%RH )

|

Offer customization services

|

|

≤ 0.2℃

(30℃ ~ 50℃)

|

≤ 0.5%RH

( 30%RH ~ 80%RH )

|

|

≤ 0.3℃

(-20℃ ~ 10℃)

|

≤ 1.0%RH

( 95%RH )

|

|

Temperature stability

|

≤ ±0.05℃

(10℃ ~ 30℃)

|

Humidity stability |

± 0.5%RH

( 5%RH ~ 30%RH )

|

|

≤ ±0.1℃

(30℃ ~ 50℃)

|

± 0.3%RH

( 30%RH ~ 80%RH )

|

|

±0.2℃

(-20℃ ~ 10℃)

|

± 0.5%RH

( 95%RH )

|