DTZ-TS Temperature Switch Automatic Calibration System

Features / Advantages

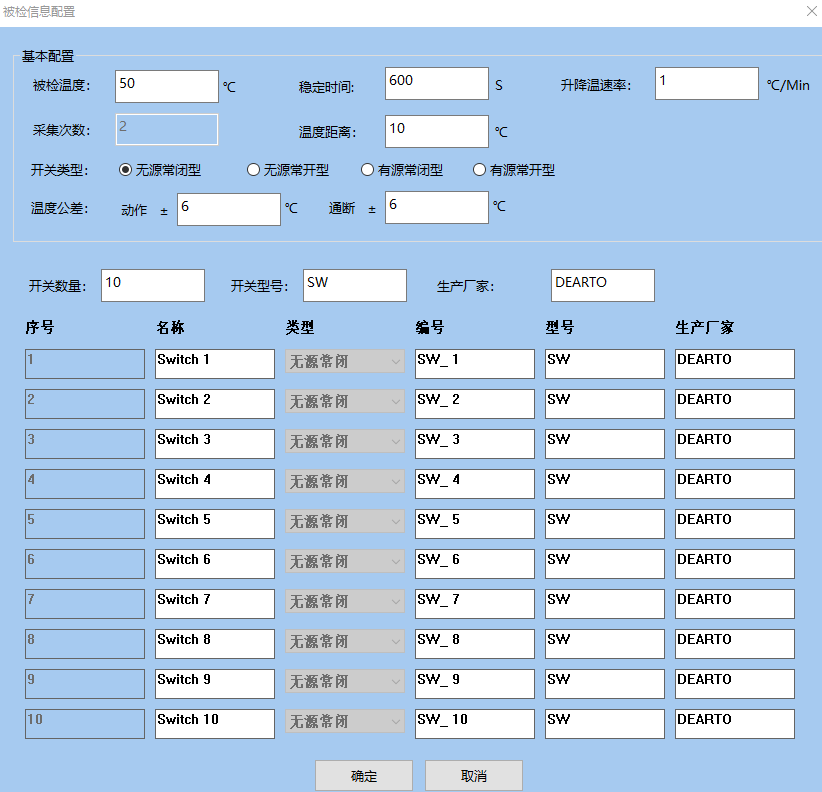

Flexible adaptation

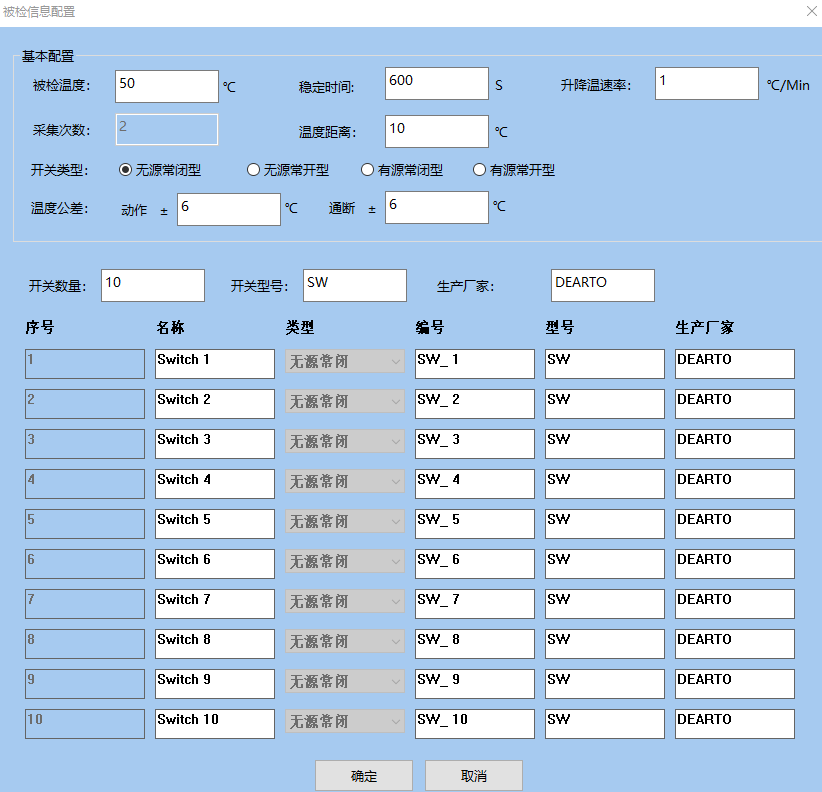

Compatible with multiple types of temperature switches: active, passive, normally closed, and normally open.

Intelligent integration of components

The scanning device powers the switches under test in real time. Supports both manual and automatic test modes. Channel indicators display switching actions in real time, integrating power supply, testing, and status indication to improve efficiency and usability.

High-precision multi-channel measurement

Equipped with a high-precision multi-channel thermometer readout with a resolution of 0.0001. Supports up to 10 channels for simultaneous verification. Ensures high accuracy and reliability to meet strict calibration requirements.

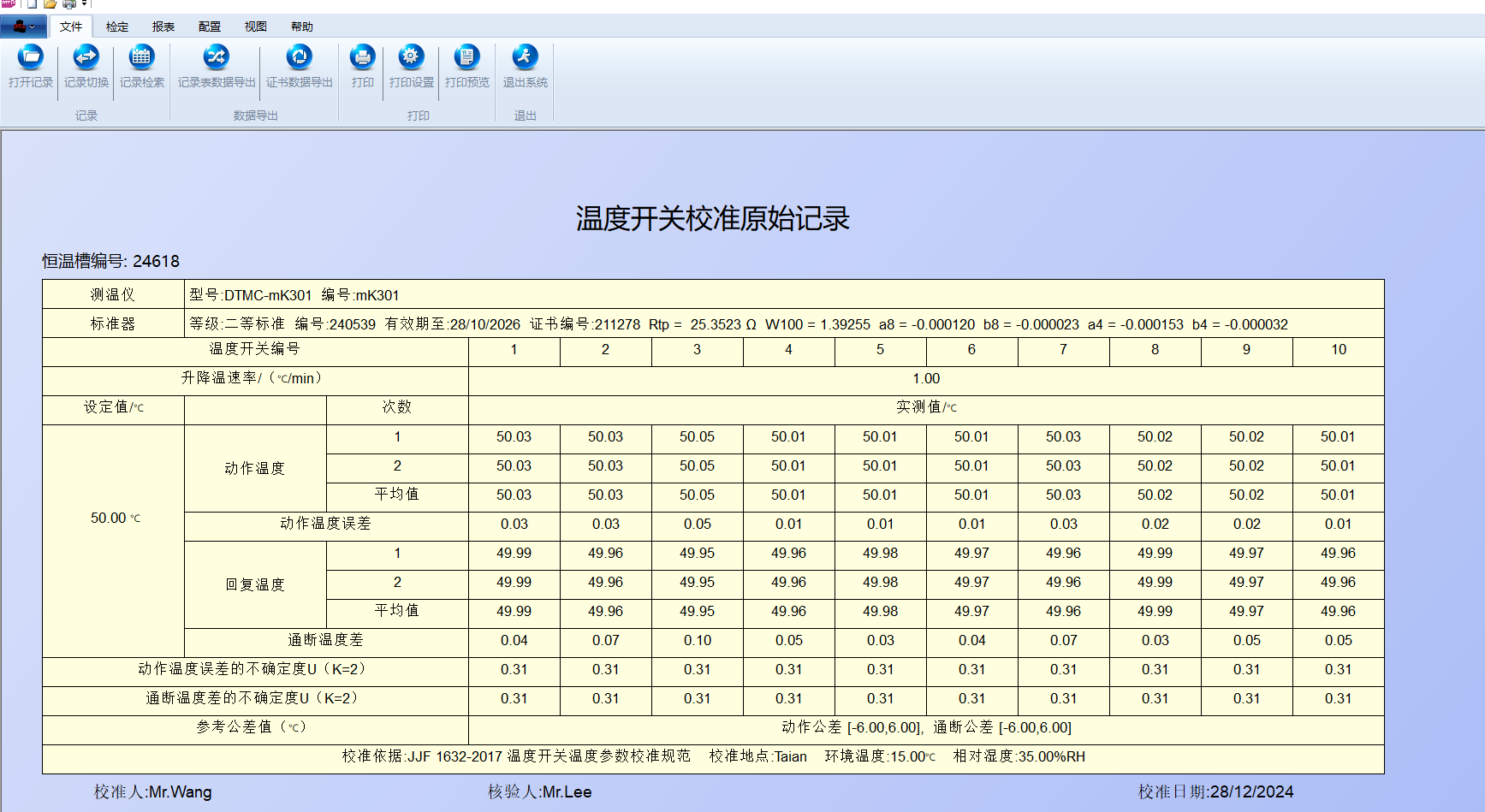

Built-in uncertainty evaluation

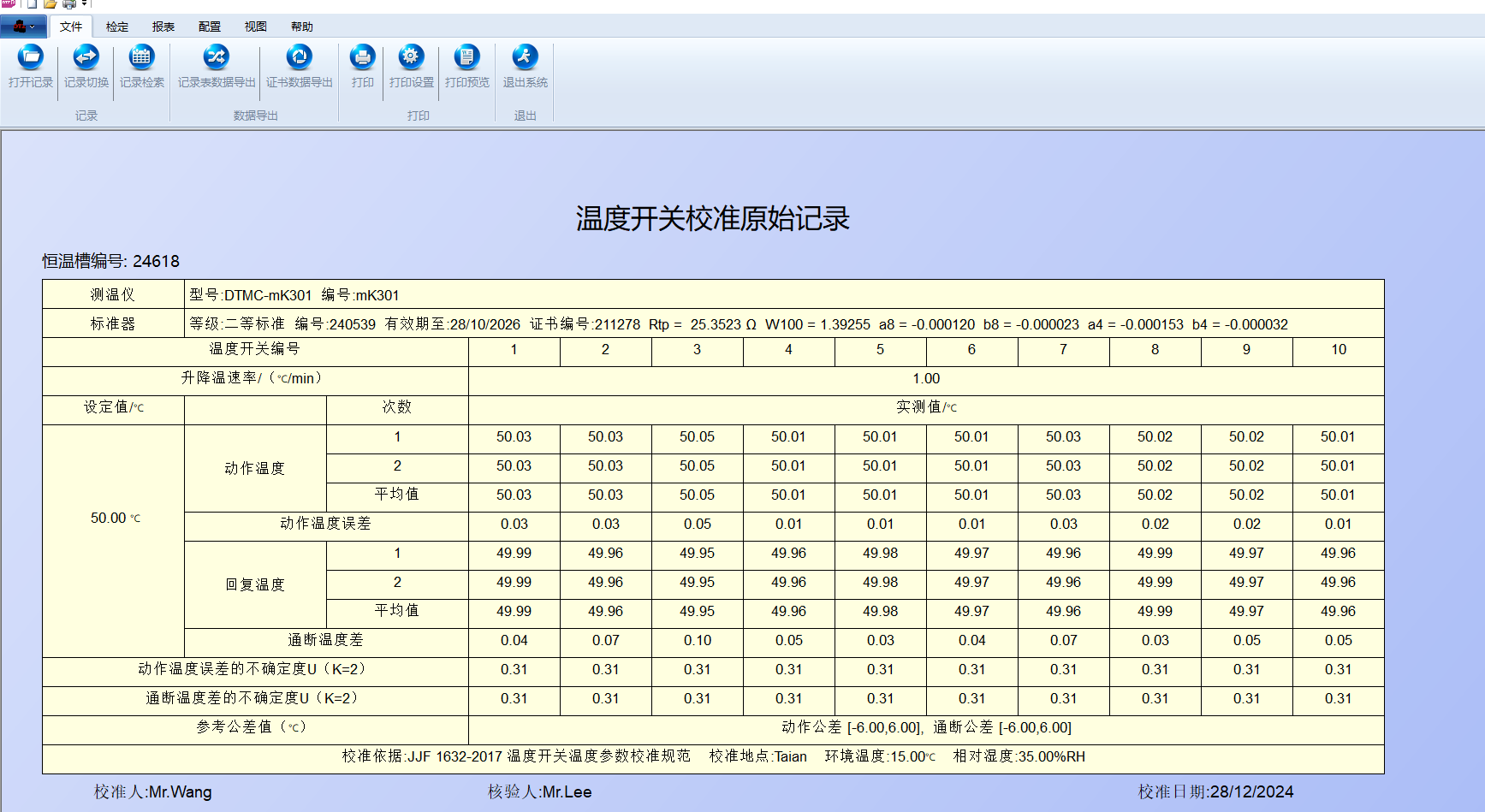

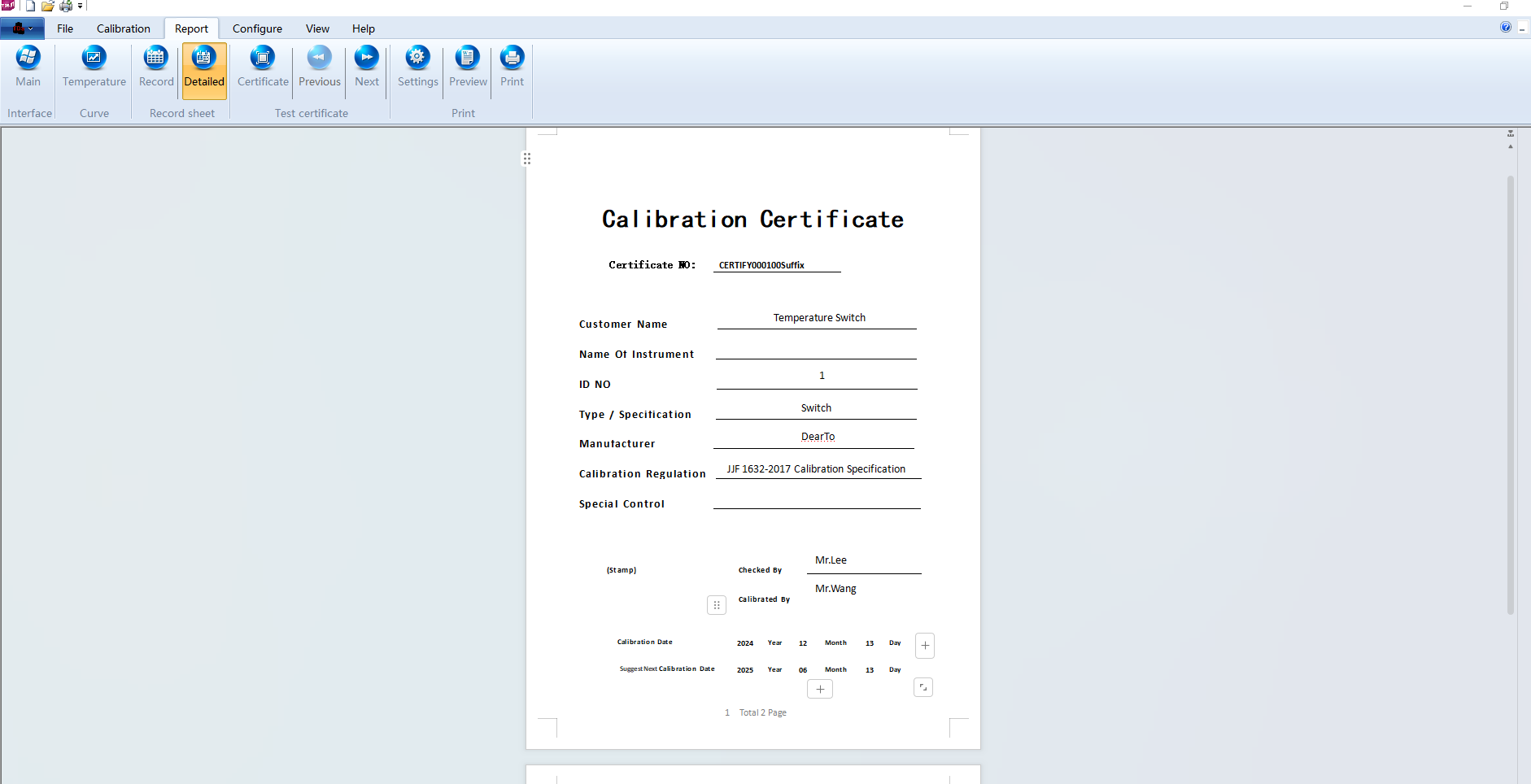

Fully compliant with JJF 1632-2017 Calibration Specification for Temperature Parameters of Temperature Switches. Includes automated calculation of combined standard and expanded uncertainty (k=2) with traceable computation records and verification reports.

Enhanced temperature stability

Utilizes a multi-stage PID algorithm with real-time temperature feedback to ensure that after heating reaches steady state, the system achieves the specified fluctuation threshold within the set time (≥10 min). Dynamic compensation strategies maintain long-term stability, meeting technical requirements for stabilization time in metrological verification procedures.

Controlled temperature ramp rates

PID-based control limits heating/cooling rates to ≤1 °C/min, ensuring smooth transitions and preventing measurement errors from rapid fluctuations.

Integrated temperature control & switch detection

Provides real-time monitoring of temperature switch state changes while precisely controlling heating and cooling of the constant-temperature bath. This enables fully synchronized automation of temperature regulation and switch testing, ensuring efficiency and accuracy in the verification process.

Intelligent error calculation & decision-making

Displays standard reference data, bath conditions, and task status dynamically. Provides intuitive feedback and transparency throughout the verification process.

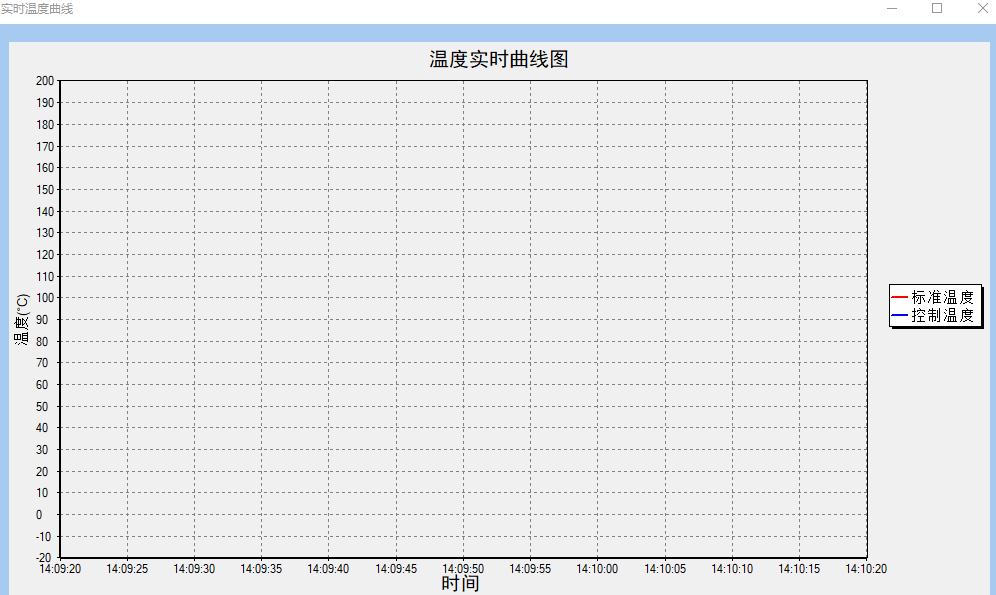

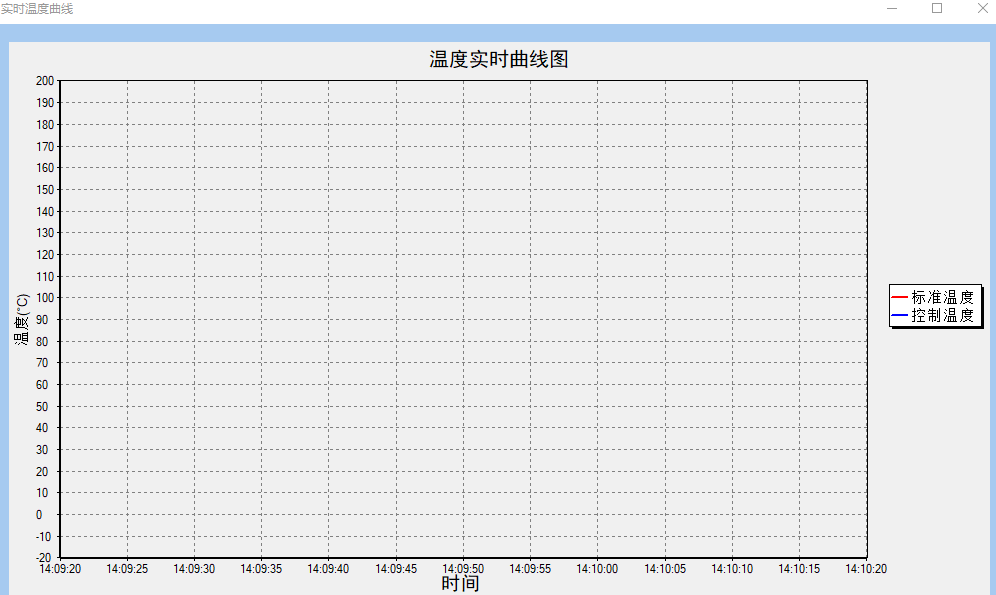

Temperature curve tracking & historical review

Real-time curve updates with access to historical data for trend analysis and traceability.

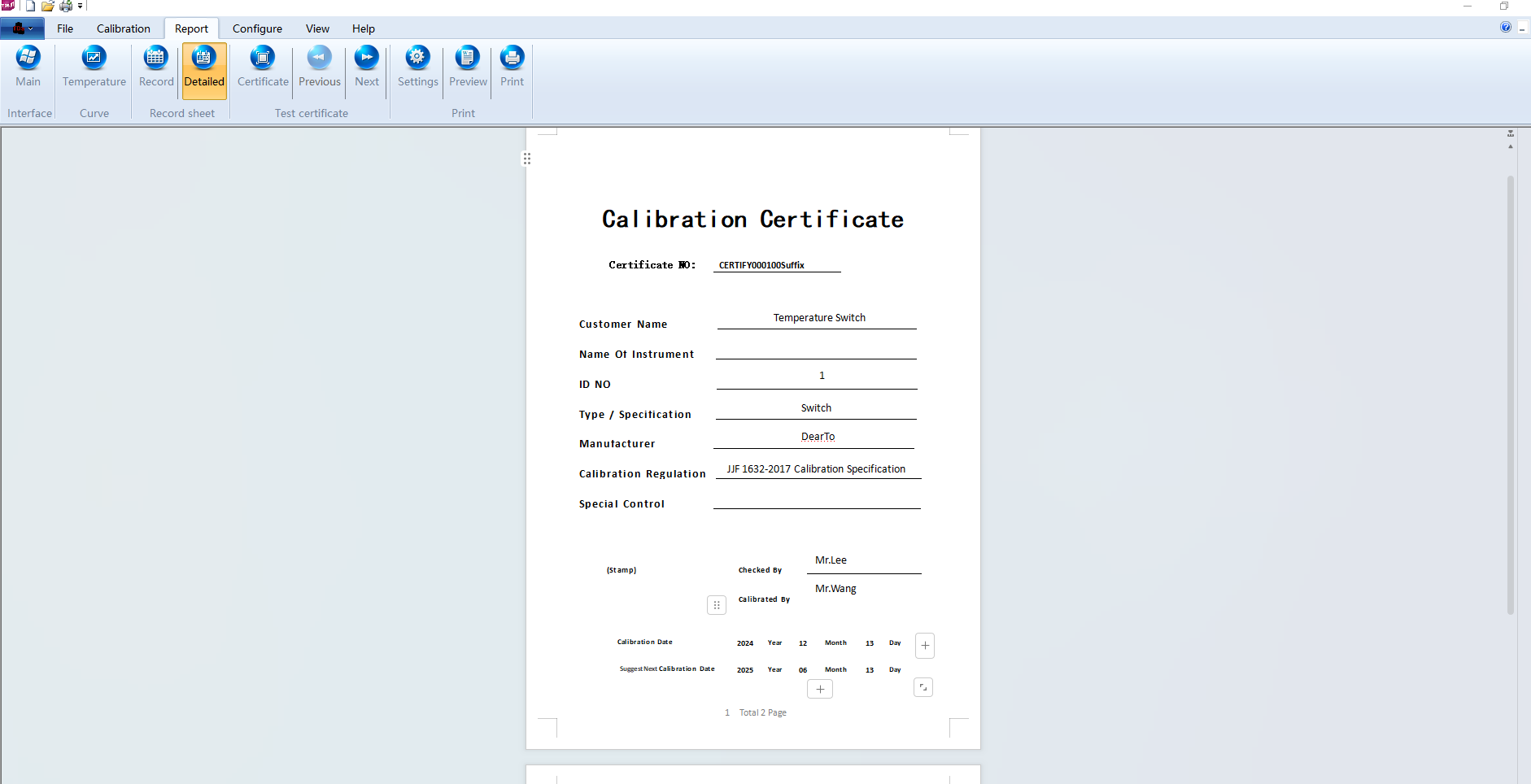

Automated reporting

Automatically generates test record tables, supporting export and printing of raw records and calibration certificates. This ensures standardized data management and convenient output in compliance with regulated verification workflows.

Efficient historical data retrieval

Supports keyword-based search, allowing users to quickly locate historical records for precise data retrieval and flexible access, significantly improving efficiency and convenience in data management.

Broad communication compatibility

Supports RS232, RS485, and Type-C interfaces for flexible integration across industrial environments.

Simplified wiring & remote extension

Employs a simplified wiring design that supports ultra-fast sensor connections and provides extension ports for long-distance testing, greatly enhancing ease of operation and adaptability to diverse testing environments.

Features / Advantages

Full parametercustomization

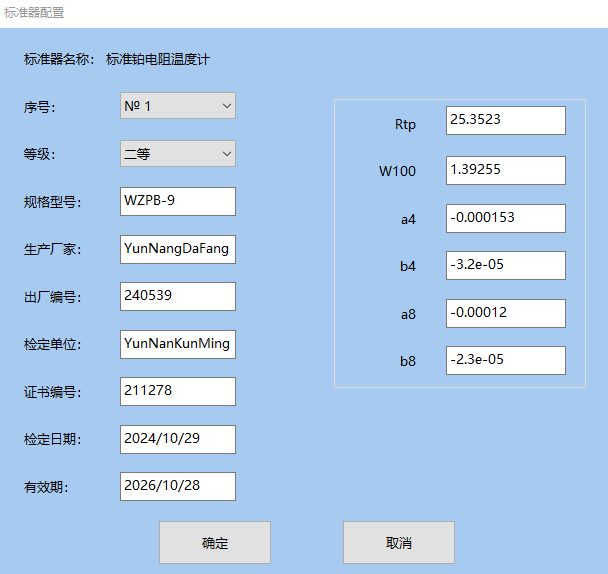

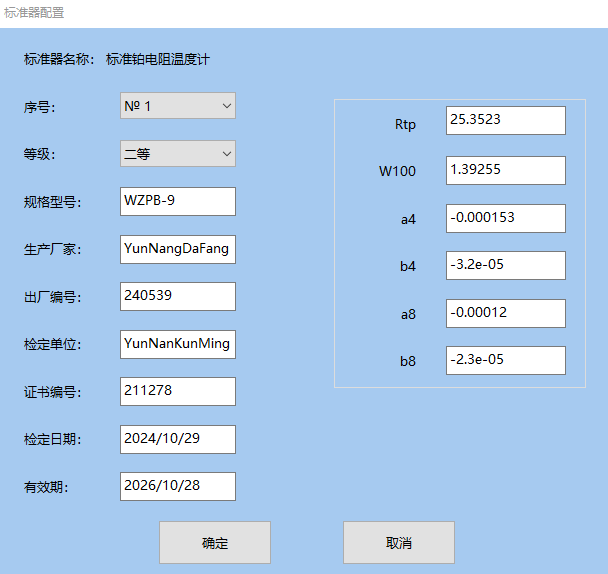

Intelligent management of standardizer information

Intelligent monitoring and visualization of the whole process

Intelligent temperature control and real-time tracking of task status

Dynamic tracking and history of temperature profiles

Intelligent computing and reporting integrated management