In a multitude of industrial and scientific applications, maintaining the accuracy and reliability of humidity measurements is paramount. From ensuring consistent product quality in pharmaceutical manufacturing to generating precise weather forecasts, humidity plays a crucial role. This is where humidity calibrators come into play. These essential instruments generate a controlled and known humidity environment, allowing users to calibrate and adjust their humidity sensors for accurate readings.

This comprehensive guide delves deep into the world of humidity calibrators, equipping you with the knowledge to select the perfect one for your specific needs. We'll explore the key factors to consider, delve into the different types of Humiditycalibrators available, and analyze practical case studies to solidify your understanding.

|

1. |

|

|

2. |

|

|

3. |

|

|

4. |

|

|

5. |

1. Key Considerations for Choosing a Humidity Calibrator

Selecting the most suitable humidity calibrator hinges on a thorough understanding of your application and its specific requirements. Here are the crucial factors to meticulously consider:

Accuracy Requirements: The cornerstone of reliable calibration lies in the accuracy of the calibrator itself. It should demonstrably surpass the accuracy of the sensors you intend to calibrate. This ensures a high-precision and trustworthy calibration process.

Humidity Range: The calibrator's ability to generate the specific humidity levels that your sensors will encounter in real-world scenarios is essential. This guarantees that the sensors are calibrated across their entire operational range, preventing potential measurement errors under various humidity conditions.

Temperature Range: Environmental conditions play a significant role in humidity measurements. The calibrator should be capable of operating within the temperature range that your sensors will experience in the field. This ensures that calibration reflects the actual operating environment and delivers accurate results.

Advanced Features and Functionality: Modern humidity calibrators offer an array of additional features that can significantly enhance your calibration experience. Consider functionalities like data logging, which simplifies record-keeping and trend analysis. Automatic calibration capabilities streamline the process, saving time and resources. Remote monitoring allows for real-time observation of calibration progress, particularly valuable in large-scale operations.

Size and Portability: The ideal calibrator should be appropriately sized and portable for your intended use. If space is a constraint, a compact chamber might be preferable. Conversely, if frequent field calibrations are necessary, a portable humidity generator offers a practical solution. Ease of use and transportation are crucial factors to consider as well.

Budget Considerations: Budgetary constraints play a vital role in the selection process. While high-precision calibrators offer superior accuracy, they come with a higher price tag. Carefully assess your needs and strike a balance between accuracy requirements, functionalities offered, and overall cost. Consider the long-term return on investment, factoring in maintenance needs and potential upgrades in the future.

2. Unveiling the Diverse Landscape of Humidity Calibrators

The world of humidity calibrators is populated with a variety of options, each boasting its own strengths and weaknesses. Here's an in-depth exploration of the most common types:

2.1 Temperature Humidity Calibration Chamber: This ubiquitous type of calibrator reigns supreme in popularity. It features a chamber meticulously controlled to maintain specific temperature and humidity levels. The sensor under test is placed inside the chamber and allowed to equilibrate with the controlled environment. Technicians then adjust the chamber's humidity level until the sensor reading matches the actual humidity, ensuring precise calibration.

2.2 High Precision Thermostatic Chamber: Designed for applications demanding exceptional accuracy, this type of calibrator elevates the precision game. It surpasses the capabilities of standard temperature humidity calibration chambers, offering unmatched accuracy for the calibration of high-precision humidity sensors. This makes it ideal for critical applications where even the slightest deviations can have significant consequences.

2.3 Automatic Temperature Humidity Calibration System: For large-scale industrial settings where numerous sensors require regular calibration, this automated system shines. It eliminates the need for manual intervention, streamlining the process and saving valuable time. Multiple sensors can be calibrated simultaneously, boosting efficiency and productivity.

2.4 Portable Humidity Generator: Compact and readily transportable, this calibrator is a boon for field applications. It generates a known humidity level, making it ideal for on-site calibrations where lugging around a bulky chamber is impractical. This allows for convenient and timely calibration without compromising accuracy.

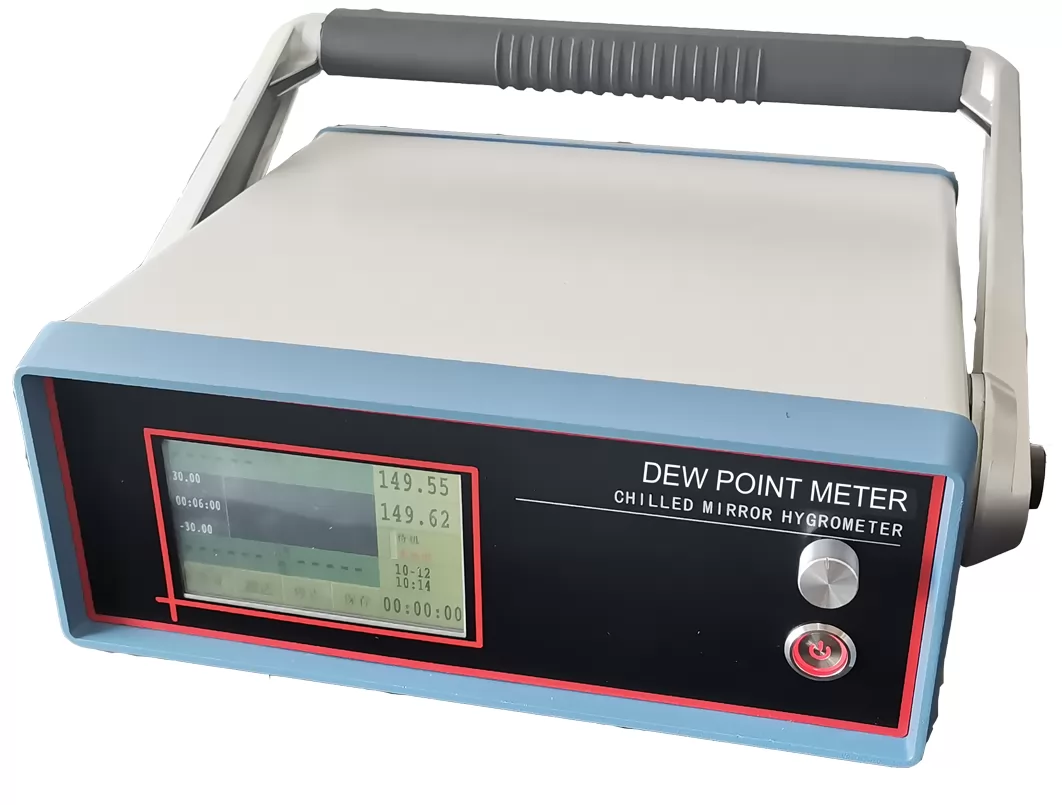

2.5 Dew Point Meter: This unique calibrator takes a different approach to humidity measurement. It measures the dew point temperature, which is the temperature at which a gas sample condenses into a liquid. By measuring the dew point, the calibrator can calculate the humidity level of the gas. This method offers an alternative approach to traditional humidity measurement techniques.

3. Humidity Measurement Techniques (In-Depth Exploration)

To further enhance our understanding of how humidity calibrators work, we need to delve deeper into humidity measurement techniques themselves. Humidity measurement involves measuring the amount of water vapor in the air, typically expressed as relative humidity

(RH), which is the percentage of water vapor present in the air compared to the amount it could hold at the same temperature and pressure when saturated. Here's a breakdown of some common humidity measurement techniques employed in various sensors:

Capacitive Humidity Sensor: This widely used type of sensor leverages the relationship between a capacitor's capacitance and the surrounding humidity level. As humidity increases, the capacitance of the sensor also increases. By measuring this capacitance change, the humidity level can be determined.

Resistive Humidity Sensor: This type of sensor utilizes the relationship between the resistance of a resistive material and the surrounding humidity. When humidity rises, the resistance of the material also increases. Measuring the resistance change allows for the determination of the humidity level.

Optical Humidity Sensor: This sensor employs optical principles to measure humidity. It works by measuring how a light beam interacts with the surrounding humidity level. As humidity increases, the behavior of the light beam changes. By measuring these changes, the humidity level can be established.

Other Measurement Techniques: Beyond the aforementioned sensor types, other techniques exist for measuring humidity, such as psychrometers, which use two thermometers (wet and dry bulb) to determine humidity based on the difference in their readings, and thin-film electrolytic cell sensors, which utilize the electrolytic process to measure moisture content.

4. The Importance of Maintenance and Calibration

To ensure the long-term accuracy and reliability of your humidity calibrator, regular maintenance and calibration are crucial. Manufacturers typically recommend periodic cleaning and servicing of the calibrator to maintain optimal performance. Additionally, the calibrator itself needs to be periodically calibrated against a traceable reference standard to guarantee the accuracy of its readings. The calibration interval will depend on the specific type of calibrator and its frequency of use.

5. Conclusion

Choosing the right humidity calibrator is critical to ensuring accurate and reliable humidity measurements in a variety of applications. By carefully considering the factors discussed in this guide and selecting the appropriate calibrator type, users can achieve accurate and reliable measurements, ultimately optimizing operational performance and efficiency.

DEARTO is committed to providing customers with high-quality humidity calibrators and services. We understand the importance of humidity measurement in various industries, and we remain committed to superior performance and reliability. We also provide professional pre-sales and after-sales services to help you choose the right product and solve any problems you encounter during use. If necessary, please contact us.