Group Furnace Automatic Calibration System for Thermocouple and Resistance Temperature Detector

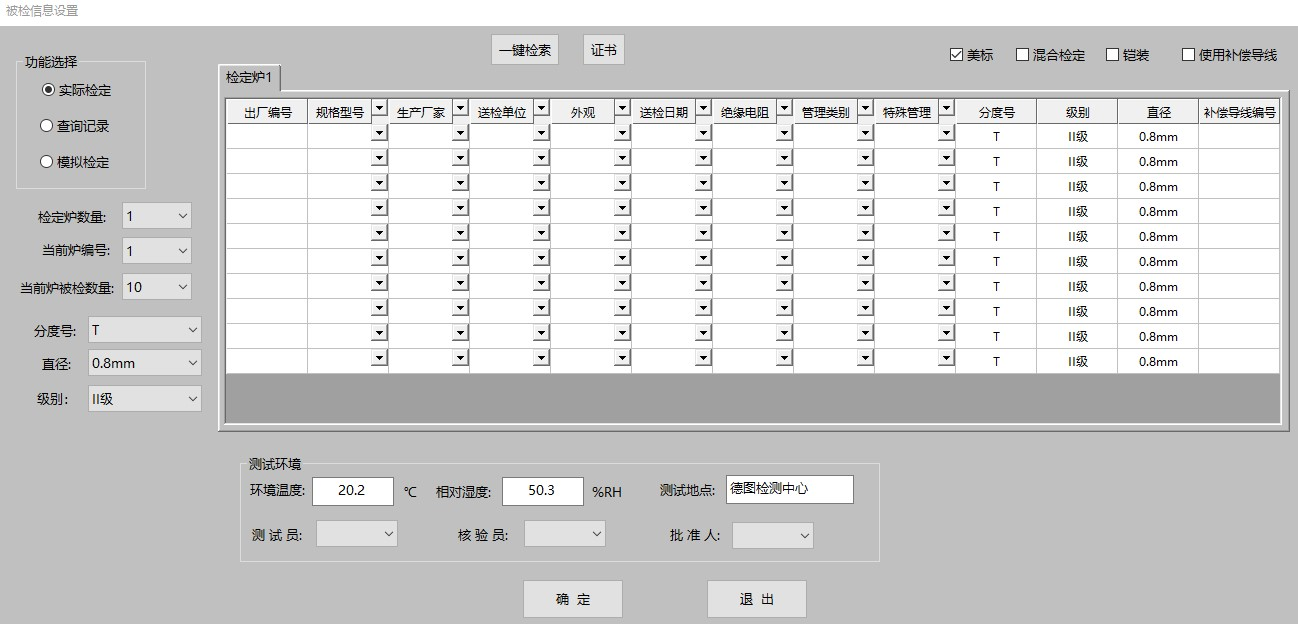

The DTZ-01 Thermocouple and RTD Automatic Calibration Systems are designed for the automatic calibration and verification of temperature sensors, including working thermocouples, industrial RTDs, liquid-in-glass thermometers, bimetallic thermometers, and pressure thermometers. The systems can simultaneously control 1 to 10 calibration furnaces, each capable of calibrating up to 10 thermocouples at once. The systems also support batch calibration of various platinum and copper RTDs, with a capacity of up to 100 sensors in a single operation, meeting high-throughput calibration needs.

This system incorporates our company's proprietary technological innovations, with all software and hardware independently developed under exclusive intellectual property ownership. Featuring advanced design, rational structure, and user-friendly operation, it ensures accurate value transmission, strong anti-interference capability, and flexible configuration. The system automatically performs data acquisition, processing, storage, and generates verification/calibration certificates to significantly improve efficiency, providing comprehensive technical assurance.

· System software supports single-furnace low-EMF scanners, dual-furnace low-EMF scanners, and multi-furnace low-EMF scanners.

· The systems support communication protocols for a variety of digital multimeters and high-precision thermometers.

· System software allows simultaneous, user-defined selection of different types of calibration furnaces and standard instruments.

· The systems support constant-temperature sources from different manufacturers, with user-selectable temperature control modes.

· Multiple thermocouple reference junction compensation methods are offered, including 0 °C thermostat compensation and automatic ambient temperature compensation.

· Temperature can be controlled using a standard thermocouple to improve accuracy, control speed, and stability.

· Power-off protection and calibration resumption prompts are available; after power is restored, the user can choose whether to continue the calibration process.

· Forced-calibration and over-temperature protection are featured to meet diverse customer testing requirements.

· The systems utilize advanced professional PID algorithms, supporting automatic PID tuning for calibration furnaces and automatic saving of parameters after tuning.

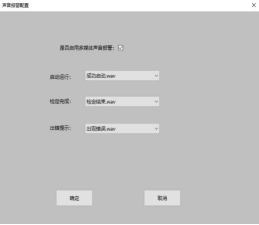

· Provides multimedia audible alarms and intelligent prompts during test startup, upon completion, and in case of errors.

· Supports automatic channel checking and filtering, with prompts for abnormal data after inspection.

· Electronic signature is supported.

· Automatically saves calibration data to the database upon completion.

· Supports grouped calibration: up to 100 RTDs can be calibrated in one session, divided into 10 groups for Pt10, Pt100, Pt-X, Cu50, Cu100, Cu-X industrial RTDs, improving testing efficiency.

· Allows input of transmitter information (0–10 mA, 4–20 mA, 1–5 V, etc.), with editable parameters including upper and lower temperature limits, accuracy, compensation wire type, and load resistance for current transmitters (default 250 Ω).

· Supports mixed calibration: each calibration furnace can be set with its own sensor type and quantity, allowing simultaneous calibration of different base-metal or noble-metal thermocouples in the same furnace, with automatic data processing and result determination.

· Displays a consolidated overview of multiple furnaces’ operating status, including current temperature, setpoint, rate of change, and progress.

· Enables fully automatic calibration, including automatic temperature control, data monitoring, data acquisition, and processing, with automatic generation of various reports and database storage; supports database search and retrieval.

· Meets or exceeds the requirements of JJF 1098-2003 Calibration Specification for Auto-measuring System of Thermocouples and Resistance Thermometers.

· Features integrated statistical management, multi-threaded design, compatibility, and self-diagnostic capability.

· Compatible with Windows 2000, XP, Windows 7, Windows 8, and Windows 10 operating systems; practical, professional, and open, supporting interfacing with equipment from multiple manufacturers.

· Core technology is independently developed with full intellectual property rights, based on national verification regulations and specifications, with dynamic simulation of calibration scenarios, providing comprehensive after-sales and upgrade support.

|

Verification/ calibration function |

Type |

Grade |

Remarks |

|

Standard Thermocouple |

S, R, B |

Grade 1/ Grade 2 |

Standard Thermocouple |

|

Working thermocouple |

S、R、short S、short R |

Class I / Class II |

Working Noble metal TC |

|

B |

Class II / Class III |

|

|

|

K, N, E, J, T, EA-2 etc |

Class 1/ Class 2 |

Base metal TC |

|

|

WRe3-WRe25/ WRe5-WRe26 |

|

Working Tungsten-Rhenium TC |

|

|

Industrial thermal resistor |

Pt100, Pt10, Pt-X, Cu50, Cu100, Cu-X |

AA, A, B, C etc |

Two-wire,three-wire, four-wire |

|

Temperature transmitter |

0-10mA, 4-20mA, 1-5V |

|

Voltage type, current type |

|

Noble Metal Thermocouple Wire |

SP, SN, RP, RN |

Standard (Grade 1/ Grade 2), Class I and Calss II |

PtRh 10 PtRh 13 |

|

BP, BN |

Standard (Primary/ Secondary), Class II, Class III |

PtRh 30 |

|

|

Platinum-rhodium thermocouple filament |

SP, SN (pure Pt) RP, RN (pure Pt) BP: PtRh 30, BN: PtRh 6 |

|

|

|

Base Metal Thermocouple Wire |

KP, KN, NP, NN, JP, JN, EP, EN, TP, TN |

Class I / Class II / Class III |

Nickel-silicon alloy Copper-silicon alloy |

|

Items |

Indicators |

Items |

Indicators |

|

Accuracy level |

0.005% |

Thermocouple cold junction compensation range |

5~50 ℃ |

|

Scanner parasitic EMF potential |

≤ 0.2 µV |

Free end resolution |

0.01 ℃ |

|

Inter-channel data acquisition deviationchannels |

≤ 0.5 µV,1.0 mΩ |

Thermocouple calibration furnace control capability |

220 V,0~40 A |

|

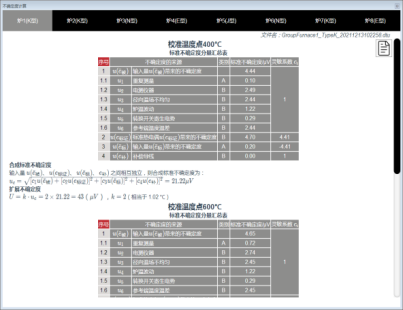

Measurement repeatability |

≤ 1.0µV,3.0 mΩ |

Set point deviation |

≤ ± 0.1 ℃ |

|

Verification of measurement data processing results |

≤ 0. 1µV,0.1mΩ |

Total expanded uncertainty of the thermocouple system |

≤ 0.68 ℃ |

|

Total expanded uncertainty of RTD system |

Standard Platinum Resistance Thermometer (Rtp) — Measurement after rechecking with a triple-point-of-water cell: RTD ≤ 0.03 °C (at 0 °C); 0.06 °C (at 100 °C) |

||

|

Standard Platinum Resistance Thermometer (Rtp) — Using value from calibration certificate: RTD ≤ 0.05 °C (at 0 °C); 0.09 °C (at 100 °C) |

|||

|

Temperature stability of working thermocouple system |

≤ 0.5 °C/6 min; measurement ≤ 0.1 °C/min |

||

|

Temperature stability of industrial RTD system |

≤ 0.01 °C/10 min; measurement ≤ 0.01 °C/min |

||

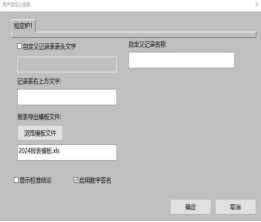

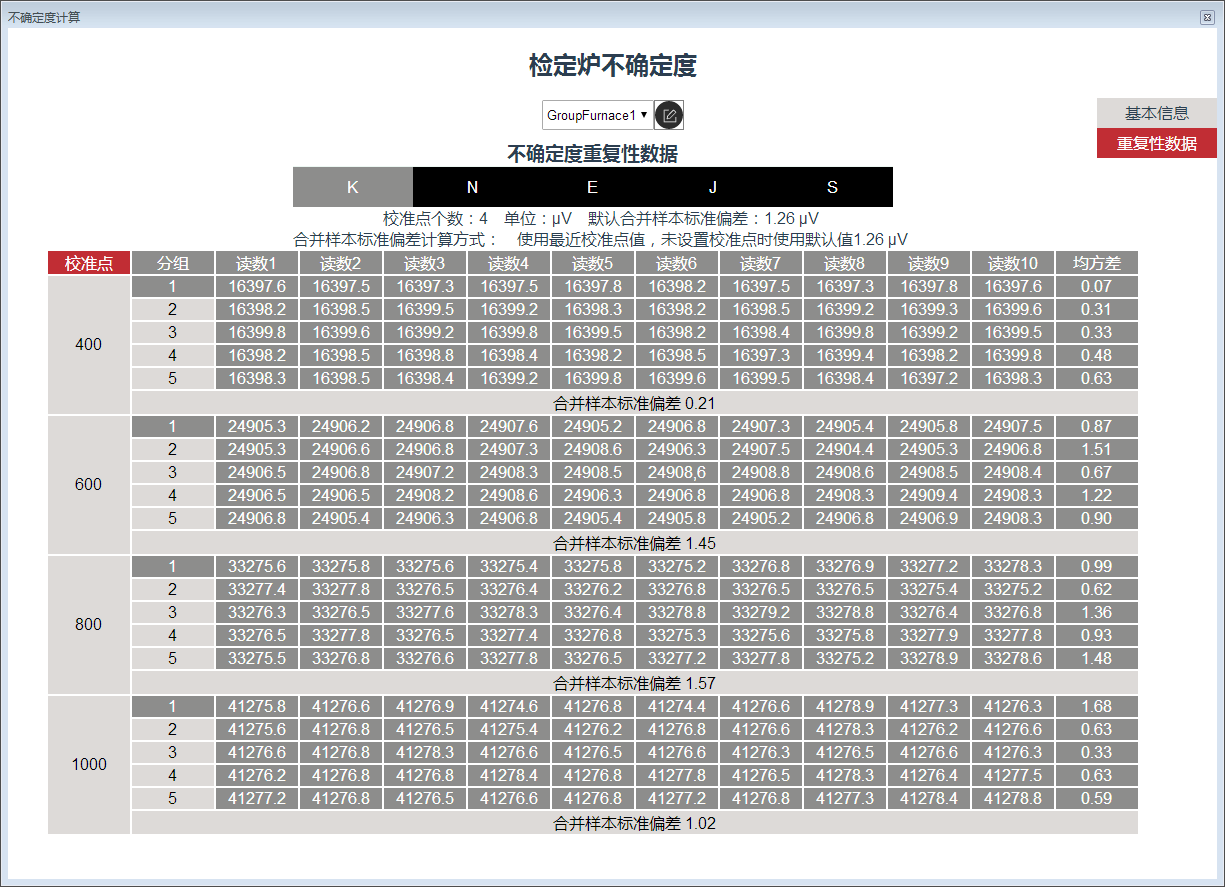

Software Interface