mK Grade High - Precision Thermometer Readout

Introduction

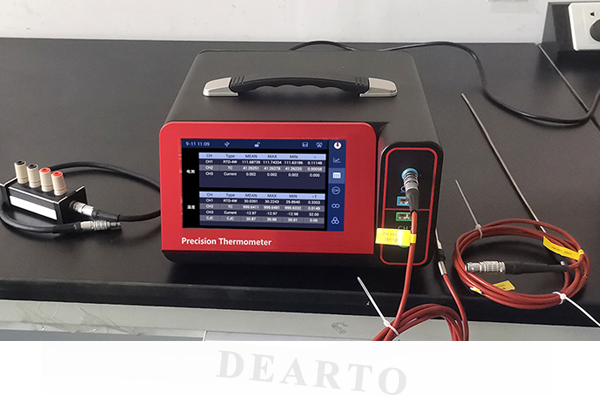

The DTMC-mK301 is a new-generation, multi-channel, ultra-high-precision thermometer readout developed for temperature metrology and calibration. It integrates high-accuracy electrical measurement technology, intelligent interface design, and application-specific functions to fully meet the calibration needs of both laboratories and fieldwork. The DTMC-mK301 measures: standard and industrial RTDs, thermocouples, thermistors, temperature transmitters, humidity sensors, DC current, resistance, and voltage signals. It supports ITS-90 and IEC 60751 standards and features built-in thermophysical conversion tools, intelligent sensor management, and broad compatibility across industries such as power, petrochemical, metrology, metallurgy, biotechnology, pharmaceuticals, and scientific research.

mK-Grade Precision Thermometer Readout

· Resolution: 0.00001 °C

· Accuracy: 5 ppm @ 0 °C (using SPRT)

Channels & Sensor Support

· 3 input channels: CH1 and CH2 (front), CH3 (rear)

· Supports 2 standard platinum resistance thermometers (SPRT), 2 standard thermocouples

· Supports RTDs: Pt (Pt25, Pt100, PtX), Cu (CuX), and Ni (NiX)

· Supports thermocouples: K, N, J, E, T, R, S, B, WRe3, WRe5

· Supports thermistors: 0 kΩ to 40 kΩ

· Supports temperature transmitters: 0 mA to 20 mA / 4 mA to 20 mA

· Automatic current reversal for RTD input to eliminate EMF thermal voltage error

Thermocouple Cold Junction Compensation

· Multiple compensation modes supported: internal compensation, external compensation, fixed compensation

Multiple Conversion Algorithms Supported

· ITS-90, Callendar-Van Dusen, IEC 60751:2008, polynomial equations, Steinhart–Hart, B-Value, linear conversion

Sensor Management Features

· Supports management of up to 100 sensor profiles

· Editable sensor parameters improve measurement accuracy

Smart Sensor Capability

· Automatic detection and data upload when a smart sensor is connected

Smart Terminal Box Support

· Stores and auto-uploads SPRT certificate values

· Plug-and-play operation; no need to manually input certificate data

User Interface & Display Modes

· Five display modes: single-channel, dual-channel, triple-channel, curve display, table display

· Real-time display of sensor information, measurement data, and trends

· Automatic statistical analysis: max, min, average, peak-to-peak, standard deviation, stability, etc.

· Real-time curve plotting

· 7-inch high-resolution capacitive touchscreen

Thermophysical Calculator

· Built-in thermophysical calculator

· Integrated ITS-90 fixed-point reference data

Data Logging & Storage

· Timestamped data recording

· 8 GB internal storage; external USB drive supported

· SCPI communication protocol over RS232/WLAN

· Screenshot feature available on all display screens, no need for manual data recording

|

Model |

DTMC-mK301G-PRT |

DTMC-mK301G |

DTHPA-mK301G |

|

Multi-channel temperature meter |

● |

● |

● |

|

DC multimeter |

|

|

● |

|

Sensor testing |

|

● |

|

|

SPRT/RTD Measurement |

● |

● |

● |

|

RTC/TC Measurement |

|

● |

● |

|

Transmitter |

● |

● |

● |

|

Thermistor Measurement |

● |

● |

● |

|

Temperature switch test |

|

● |

|

|

Constant temperature source test |

● |

● |

● |

|

Electronic scanning switch |

● |

● |

● |

|

Smart Sensors |

● |

● |

|

|

Smart Junction Box |

● |

● |

|

|

Thermal Calculator |

● |

● |

● |

|

Sensor Management |

● |

● |

● |

|

Data storage |

● |

● |

● |

|

Smart Communications |

● |

● |

● |

Technical Parameters

|

General technical indicators |

|

|

Screen |

7-inch high-definition touch screen |

|

Resolution |

Temp.:0.1 to 0.00001℃ are available;Resistance: 0.01 mΩ; Voltage: 10 nV |

|

Channel |

Front panel:2 Channels; Rear panel:3Channels;External 8-Channel Electronic Scan Switch (Optional) |

|

Data storage |

Built-in 8G storage, all stored data are time-stamped |

|

Communication interface |

COM2 |

|

Language |

Chinese, English |

|

Power supply |

110V±10%;220V±10% AC voltage shift pulley |

|

Product size |

270mm×260mm×145mm |

|

Weight |

Weighing of single host (3.39 kg) host+accessories (4.32 kg) host + accessories + packaging (6.93 kg) junction box (0.15 kg) |

Application Accessory

Overview: