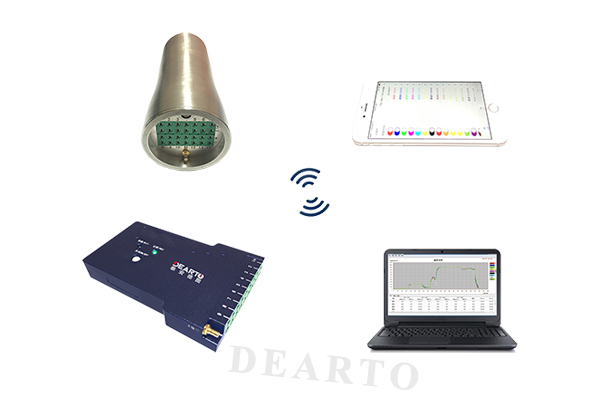

DTZ-500 Wireless Furnace Temperature Tracking & Testing System

Product Description

Technical Parameters

|

Number of measuring point |

18 channels |

Precision |

±0.4℃ |

The sensor |

K type TC |

Temperature range |

0~1300℃ |

|

At furnace time |

Customized according to usage scenarios |

RAM |

8GB(large memory, data can be stored permanently) |

||||

|

The sampling period |

Within 1s ~ 60s, it can be set by itself according to the test requirements |

||||||

|

Battery |

Rechargeable polymer lithium battery 2200mAh, can be used continuously for 50 hours; Fast charging for 15 minutes, if you turn on the wireless, you can charge for 13 hours when you charge it once. |

||||||

|

Computer requirements |

Windows 98, 2000, XP, vista, win7, etc., can be connected to the print temperature curve |

||||||

|

Heat insulated incubator size |

Customized by usage scene |

||||||

|

Instrument description |

Main chip: temperature sensitive high resolution host chip imported from USA Insulation material: Germany imported nano insulation materials Housing: high temperature & corrosion resistant stainless steel TC sensor: GB 1 |

||||||

Software Features

Product Features

- This instrument adopts an imported TF memory chip, and any accident will not lose data

- Simultaneously store 8G group data, exceeding automatic coverage;

- One-button operation, manual, temperature, and time start, simple and quick to use, self-developed full Chinese setting and data analysis software, the operation is clear at a glance.

- In addition, the upgraded version of the instrument can be connected wirelessly through a PC or ios system mobile terminal to display temperature curve data in real-time.

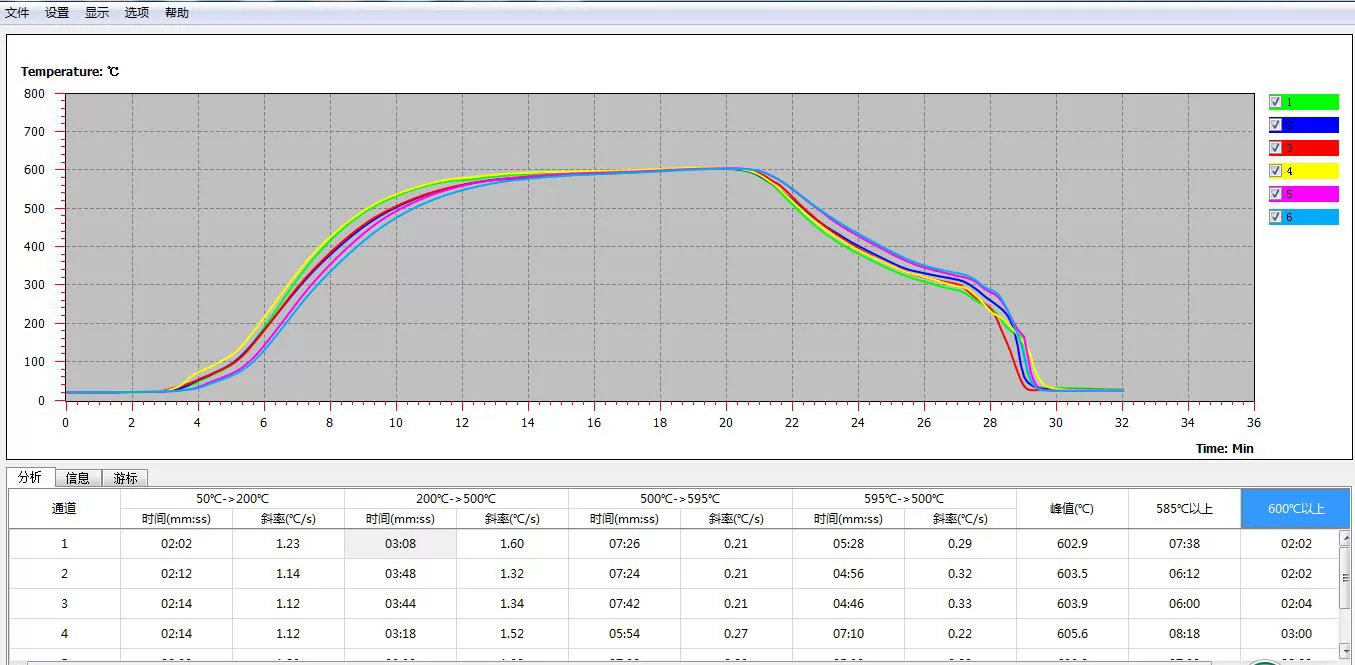

PC software curve chart

Temperature Measurement Process

- According to the customer's requirements and the use environment, use a furnace temperature tracker to measure the temperature, connect the thermocouple, put it in the heat insulation. box, and cover the heat insulation box to prevent heat leakage.

- Turn on the mobile phone, iPad, or desktop computer to control the furnace temperature tracker in real-time and analyze the temperature data in real-time.

- In order to obtain the real heating temperature of the part, the thermocouple is fixed on the part.

- After the heat treatment is over, the recorder is taken out after the thermal insulation box has cooled down.

The Main Purpose

- Digitalization of the coating process, determination of different curing temperature systems and real-time temperature curves, heating temperature and temperature difference.

- Test the curing temperature and temperature difference of the workpiece under different temperature systems and different output conditions.

- Furnace temperature uniformity test.

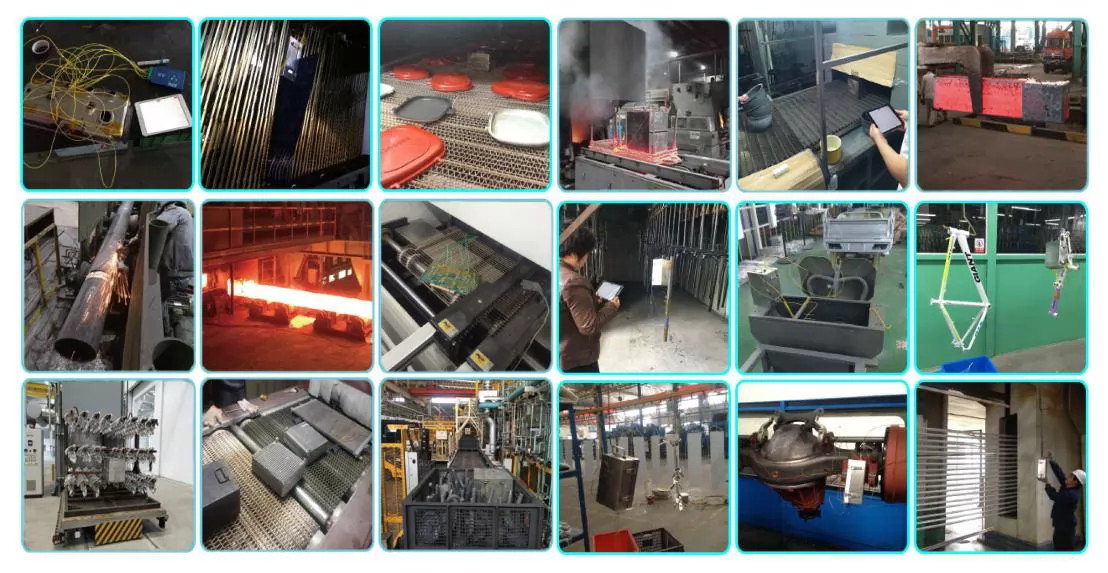

Use Scene Graph